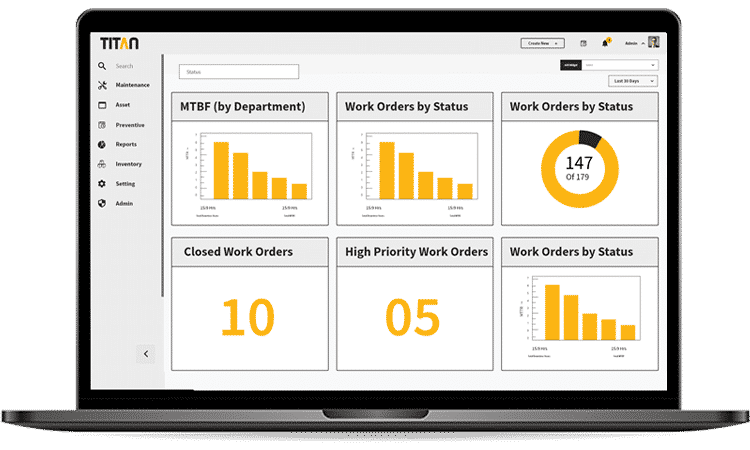

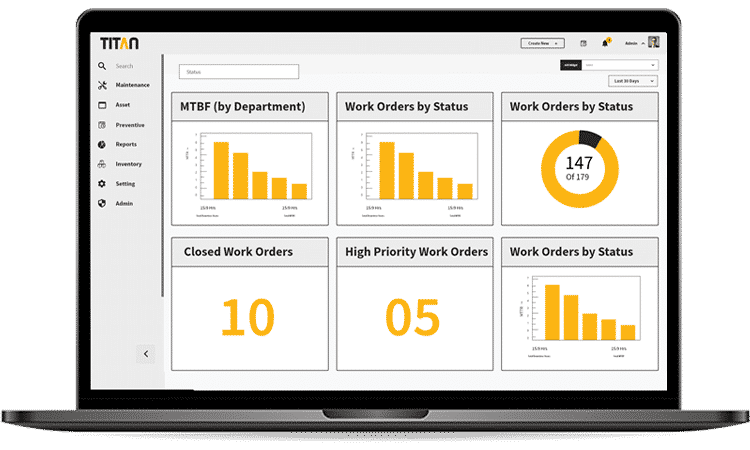

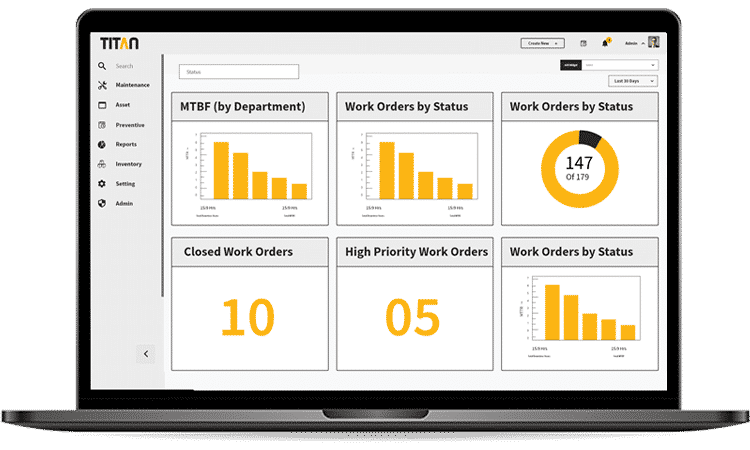

Dashboard

- Analyze asset performance metrics.

- Identify recurring failures and expedite resolution.

- View spare parts requirements and usage trends.

- Review unplanned material usage.

- Review and act on cost overrun and scheduling delays.

Get Your Free CMMS Demo Today!

Explore! Best CMMS Software to Track, Plan & Optimize Maintenance Operations. Manage assets, inventory, job orders, dashboards, reports & alerts all in one platform. Experience the top CMMS software designed for all industries.

Titan CMMS (Computerized Maintenance Management System) is the best CMMS software built to help businesses streamline maintenance operations, reduce downtime, and extend asset life. Designed by maintenance professionals, Titan CMMS combines advanced features like predictive maintenance, automated alerts, real-time dashboards, and data-driven reports to support smarter decision-making.

Our free CMMS software helps organizations manage assets, work orders, budgets, and compliance efficiently — from a single, intuitive platform. Trusted by industries worldwide, Titan delivers the reliability, transparency, and innovation expected from a top CMMS software in 2025.

As one of the best CMMS software solutions, Titan CMMS is built by maintenance experts to simplify operations, improve reliability, and reduce costs. Designed for all industries, Titan helps teams plan, execute, and track maintenance work with accuracy and transparency. Here’s how your organization benefits:

TITAN CMMS enable you to connect your plant and machinery to your maintenance management system through smart sensors and other IIOT techniques. This enables your maintenance management system to be smart enough to generate and schedule maintenance activity requirements automatically for assets

From manufacturing plants to healthcare facilities, Titan CMMS is trusted across industries as a top CMMS software for maintenance automation and asset management. Our Computerized Maintenance Management System helps streamline operations, reduce downtime, and improve equipment reliability in production, facilities, fleet, and linear asset maintenance. Designed by experts, Titan CMMS adapts to your business needs with flexibility and precision. Experience how our free CMMS software can optimize performance across any industry.

We have reduced our yearly maintenance budget 25%-30% by efficiently planning the maintenance and productively use our resources with TITAN. We have improved resource utilization up to 60% and we have reduced 40% work force allocated for maintenance. maintenance is not centric to specific person but anyone who uses TITAN can fix most problems. We have reduced downtimes of production by 50%. Maintenance couldn’t have been a simple job without TITAN.

MUDASSIR SALEEM (Managing Director of Salim Winding Works- Candle Threads)

Posted onTrustindex verifies that the original source of the review is Google. Best available CMMS software in Pakistan. I was thoroughly impressed with its ease of use, customizable features, and efficiency. Scheduling work orders, tracking assets, and managing preventive maintenance became incredibly simple.Posted onTrustindex verifies that the original source of the review is Google. Titan CMMS is a user-friendly, cloud-based solution perfect for streamlining maintenance operations. It offers automated work orders, preventive maintenance scheduling, and mobile access—all in an intuitive interface. Great for reducing downtime and improving efficiency!Posted onTrustindex verifies that the original source of the review is Google. Titan CMMS has really simplified our maintenance work. It's easy to use, helps us stay organized, and the support team is always helpful. Definitely a good choice for managing maintenance tasks.Posted onTrustindex verifies that the original source of the review is Google. My warehouse inventory problems are now solved with Titan CMMS.Posted onTrustindex verifies that the original source of the review is Google. Titan CMMS is a powerful and user-friendly maintenance management system. It helps streamline asset management, work orders, and preventive maintenance with ease. The software is highly customizable to fit different industries. Excellent support and a great solution for optimizing maintenance operations!Verified by TrustindexTrustindex verified badge is the Universal Symbol of Trust. Only the greatest companies can get the verified badge who has a review score above 4.5, based on customer reviews over the past 12 months. Read more

A CMMS (Computerized Maintenance Management System) is software that helps businesses manage maintenance operations, assets, work orders, and preventive maintenance schedules in one place.

CMMS stands for Computerized Maintenance Management System — a tool designed to streamline maintenance processes and improve equipment reliability.

A CMMS collects and organizes maintenance data to automate tasks like scheduling, tracking work orders, managing spare parts, and analyzing reports — helping teams make data-driven maintenance decisions.

A CMMS focuses on managing maintenance activities and work orders, while an EAM (Enterprise Asset Management) system provides a broader view, covering asset lifecycle management, procurement, and financial planning.

CMMS experience refers to hands-on knowledge of using maintenance software to plan, schedule, track, and analyze maintenance operations efficiently.

CMMS skills include data entry, work order management, preventive maintenance planning, asset tracking, and generating reports for performance analysis.

The best CMMS software offers an intuitive interface, mobile access, real-time dashboards, and automation tools. Titan CMMS is one of the top CMMS software solutions. Powerful, user-friendly, and suitable for all industries.

A CMMS focuses on managing maintenance activities and work orders, while an EAM (Enterprise Asset Management) system provides a broader view, covering asset lifecycle management, procurement, and financial planning.

CMMS software is used by maintenance teams, facility managers, asset managers, and operations leaders in industries like manufacturing, healthcare, real estate, and utilities.

Yes. CMMS software like Titan CMMS is scalable and affordable, helping small and medium businesses organize maintenance tasks, track assets, and grow efficiently without extra complexity.

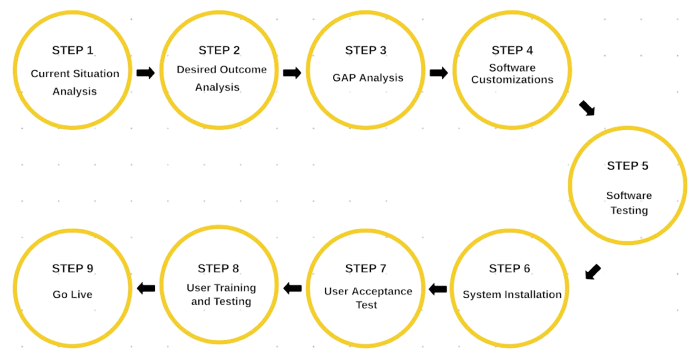

The project takes approximately 4 to 8 Months (can be varied according to industry size and customer requirements)

Experience how Titan CMMS helps you manage assets, automate maintenance, and cut downtime.

Trusted by businesses worldwide — your journey to smarter maintenance starts now.