Features Of TITAN CMMS

Asset Maintenance Software for Facilities, Plants, Machinery, and More!

Key Modules

Asset Management

Equipment Failure Recording

Planned Preventive Maintenance

Health & Safety Assessment

Health & Safety Assessment

Stock Inventory Control

Inspection/Health Monitoring

Reporting

Top Features

Tracking Work Orders

Maintenance managers can select equipment with a problem and assign a specific technician to do the work.

External work requests

Maintenance teams often have to take a work request from people outside the team.

Scheduling Tasks

As a team starts to schedule preventive maintenance, they need a reliable work calendar.

Audit & Certification

Many MMS systems keep an unchangeable record of every action, so an asset’s maintenance history can be audited.

Recoding Asset History

Many maintenance teams have to care for assets that are 10, 20, even 30 years old. These machines have a long history of repairs.

Managing Inventory

Maintenance teams have to store and manage a lot of inventory that include things like spare parts for machines and supplies like oil and grease.

Inventory & Asset Management

Reduce:

- Stock waste

- Human intervention

- Time to diagnose

- TAT

Improve:

- SOPs and best practice compliance

- Resource utilization

- Quality control

- Maintenance tracking & history

Workflow Improvements

Reduce:

- Unnecessary paper work

- Communication delays

- Data fragmentation

Improve:

- Accountability & prioritization

- Safety

- Forecasting and planning

Cost Reduction

Reduce:

- Unplanned shutdowns

- Overtime

- Average time to repair

Improve:

- Asset life

- Budget efficiency

- Budget utilization

Tracking & Reporting

Reduce:

- Average MTTR

- Average MTBF

- Preventive maintenance waste

Identify:

- Cost footprints

- Audit logs

- Productivity black holes

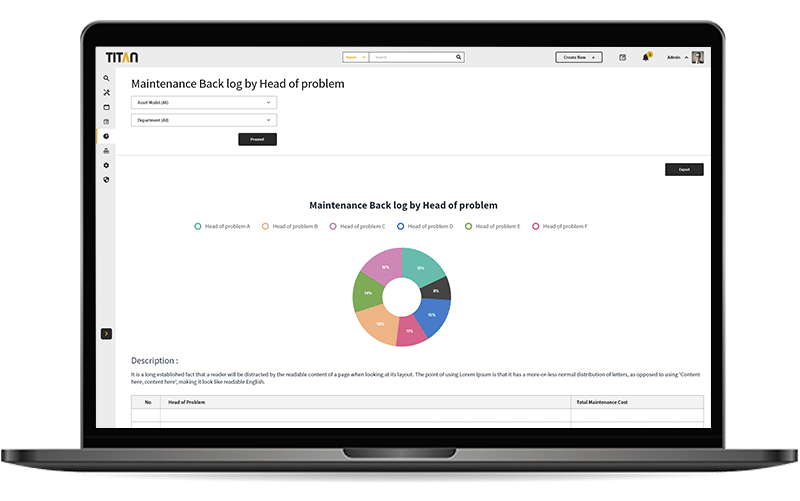

Maintenance backlog

Maintaining an Accurate Maintenance backlog is an essential piece of your company’s puzzle.

Backlogs can ensure your equipment remains in proper working order to avoid costly repairs and interruptions to your schedule. They’re critical in effective planning and scheduling. But most importantly, keeping up with tasks can prevent hazards that could put your employees in danger.